Tuned Mass Damper – Low Frequency

Product Characteristics

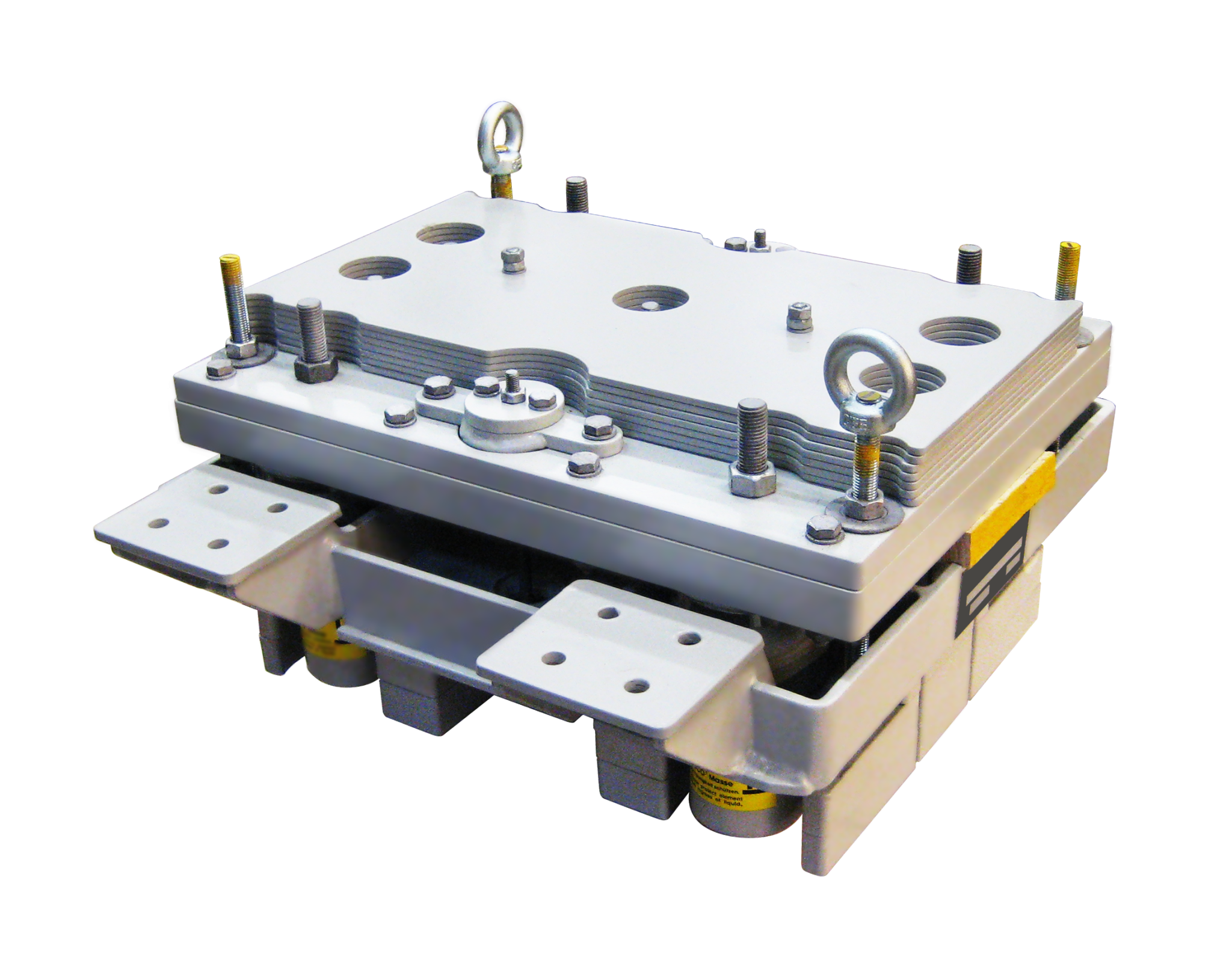

A tuned mass damper typically consists of a mass attached to a structure via springs and dampers. When the structure vibrates, the mass moves in the opposite direction, counteracting the vibration and reducing the overall movement of the structure. This helps to improve the stability, safety, and comfort of buildings, bridges, and other large structures by minimizing sway and oscillations.

A TMD is a customized product and is designed and manufactured according to the given specifications. In each case the TMD is designed to a tuning frequency Ft, which can be found when the natural frequencies of the main structure is known. TMD Mass, TMD damping coefficient and spring configuration is estimated by optimising and finding the minimum response for a main system + TMD, by solving the related differential equations.

Finite element analysis may also be used to predict the overall global response with a TMD implemented in the FE model.

TMD: Range from 50 kg

TMD: Range from 0.5 Hz – 30 Hz

TMD frequency: ± 10 %

Color and surface treatment: acc. requirements

Installation type: acc. requirement

Product Applications

Applications and General theory of TMD

Tuned mass dampers are usually implemented in the following typical application types:

- Pedestrian bridges and staircases etc. which can be excited by jumping or walking. Primarily this is a comfort problem and not a structural problem.

- Office floors and similar being excited either by jumping and walking or machinery. May cause discomfort as well as structural problems.

- Subsea oil & gas transmission lines. Excitations by wave loads.

- Tall and slender structures, like bridges, chimneys and towers which can be excited easily by wind causing dangerious situations for the structure.

Example 1: Pedestrian bridge in Malmö

Read more about it in our case study

During the structural design of the pedestrian bridge at Bagers Plats in Malmö, it became obvious that it would require a TMD, as the lowest vertical eigenfrequency was calculated to 1.85 Hz. Vibratec designed a TMD solution. In total 2 TMD’s with a vibration mass of 340 kg each was installed in the mid section of the bridge.

Damping ratio of bridge with blocked TMD: 1.5 %

Damping ratio of bridge with TMD: 9.0 %

Due to the increased damping of the first vertical modeshape, the movements by walking persons are dampened, and the comfort criteria are met.

Example 2: TMD below office floor

This is an NON classical TMD solution, as it consists of a sandwich plate with constraining damping layer. Placement of support points, dimensions of plate results in a tuning frequency similar to the actual bending mode of the floor.

A normal TMD with springs and dampers may also be used.

As the floor is a 2D structure, several TMD’s must be installed in order to reduce responses at a given modeshape.

The preliminary design of a TMD to a pedestrian bridge is based on classical theory using the SDOF method, as the dynamic behaviour of the structure is described by a linear combination of several different harmonic ossicilations. The structure can therefore be transformed into different equivalent mass spring ossicilators each with a single degree of freedom.