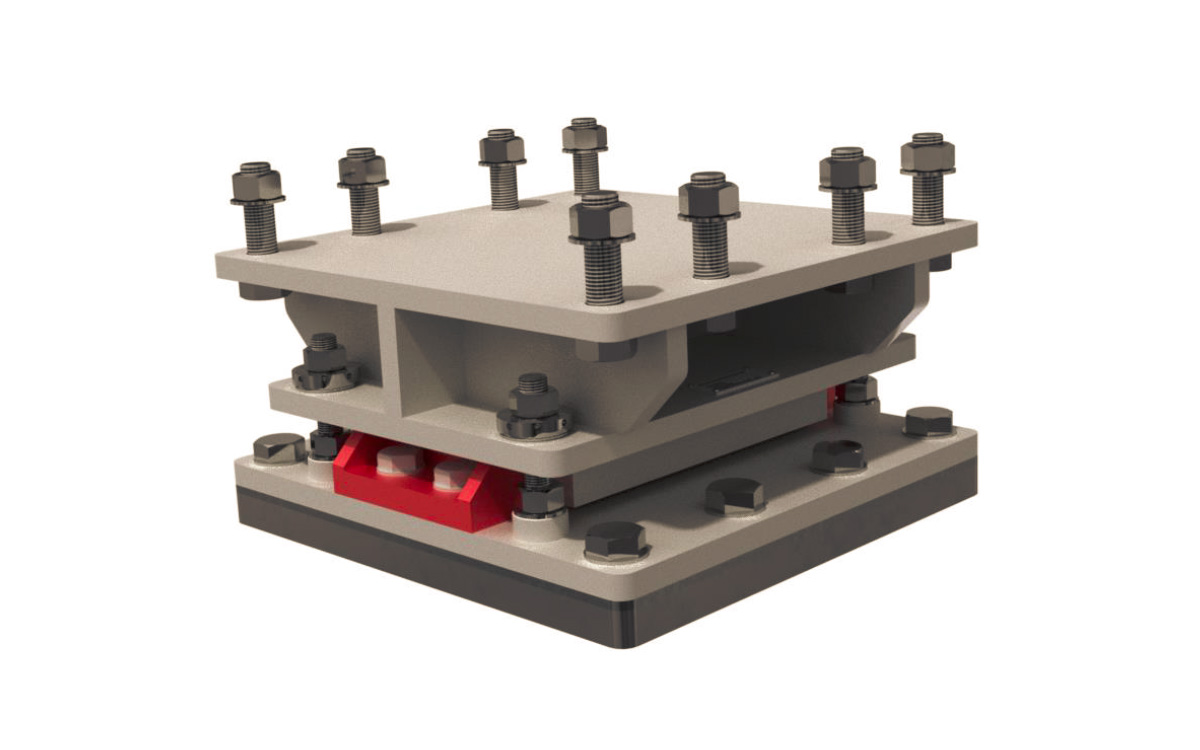

Steel Mount AVM

Product Characteristics

The cushion isolators are optimized for medium to high resonance frequency, high environmental demands and external forces such as wind, waves, accidental loads etc.

Depending on the choice of cushions, resonance frequencies from 8 to 15 Hz can be achieved.

The stiffness can be tuned by pre-compressing the built-in snubbers.

This will also add damping to the isolators resulting in a lower amplification factor.

Maximum excitation amplitude: ± 1 mm.

Temperature range: -90 °C to +300 °C.

Product Applications

Elastic suspension of rotating machinery at >1200 rpm – fans, compressors, generator sets, reciprocating machinery etc.

Protection of equipment, accommodation and office modules from vibration fatigue, noise pollution, and impacts. While also allowing movement and rotation to occur without strain or damage to the connection points.

Technical documentation

We provide extensive technical support in the use of our products and systems. This can include:

- Material certificates (related to project requirements, labtests etc.)

- Engineering results (computer calculations, on-site support etc.)

- Drawings in AutoCAD or Inventor (2D installation plans, 3D presentations etc.)

- Tests to evaluate mechanical and long-term behavior

- Manuals for maintenance and installation

- Welding, Painting and Weighing certificates

Calculations

With an extensive experience in the field, combined with use of modern tools, Vibratec are able to custom design cushion isolators that meets your requirements of vibration isolation.

Necessary calculations to ensure the performance of the system are regularly carried out. This can include:

- Mechanical strength analysis by Finite Element Methods (FEM)

- Modal analysis by use of Statistical Energy Analysis (SEA) or Finite Element Methods (FEM)

- Load distribution calculations

- Fatigue calculations

- Resonance frequency and attenuation calculations

- Calculation of fastening bolts or welds