Regupol Vibration Isolation

The building authority approved REGUPOL vibration range offers a portfolio of eight product types which can be used in the wide load range between 0.002 N/mm² and 1.5 N/mm². This creates many possibilities to implement an isolation concept for projects in the field of building services and HVAC equipment, machines, pools and gyms, as well as vibration protection for buildings, especially those in close proximity to rail infrastructure.

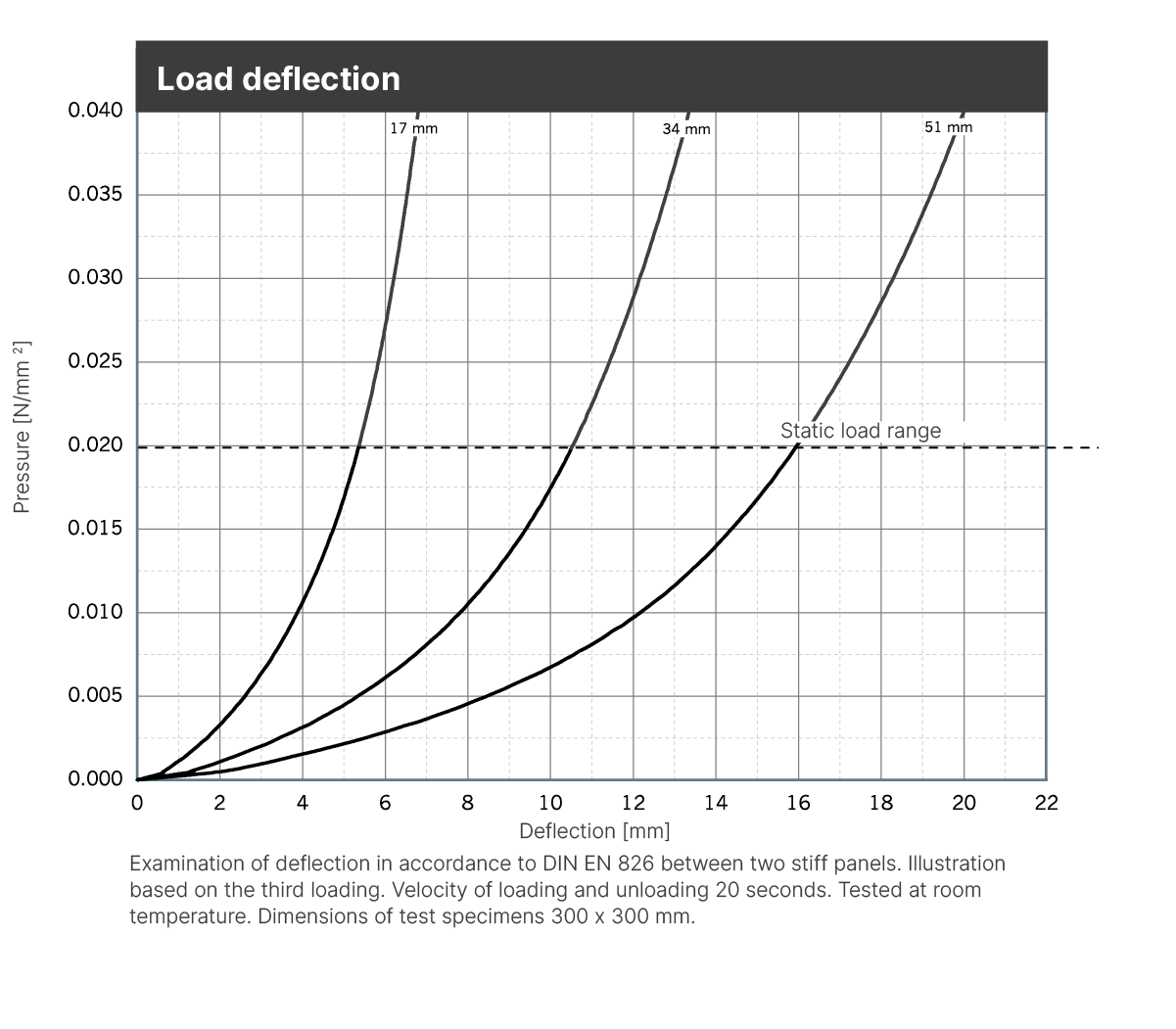

Regupol® vibration is a rubber-polyurethane-composite for vibration isolation. It can be used in single or multiple layers to achieve natural frequencies of down to 10 Hz, depending on load and material thickness.

Regupol Vibration 200

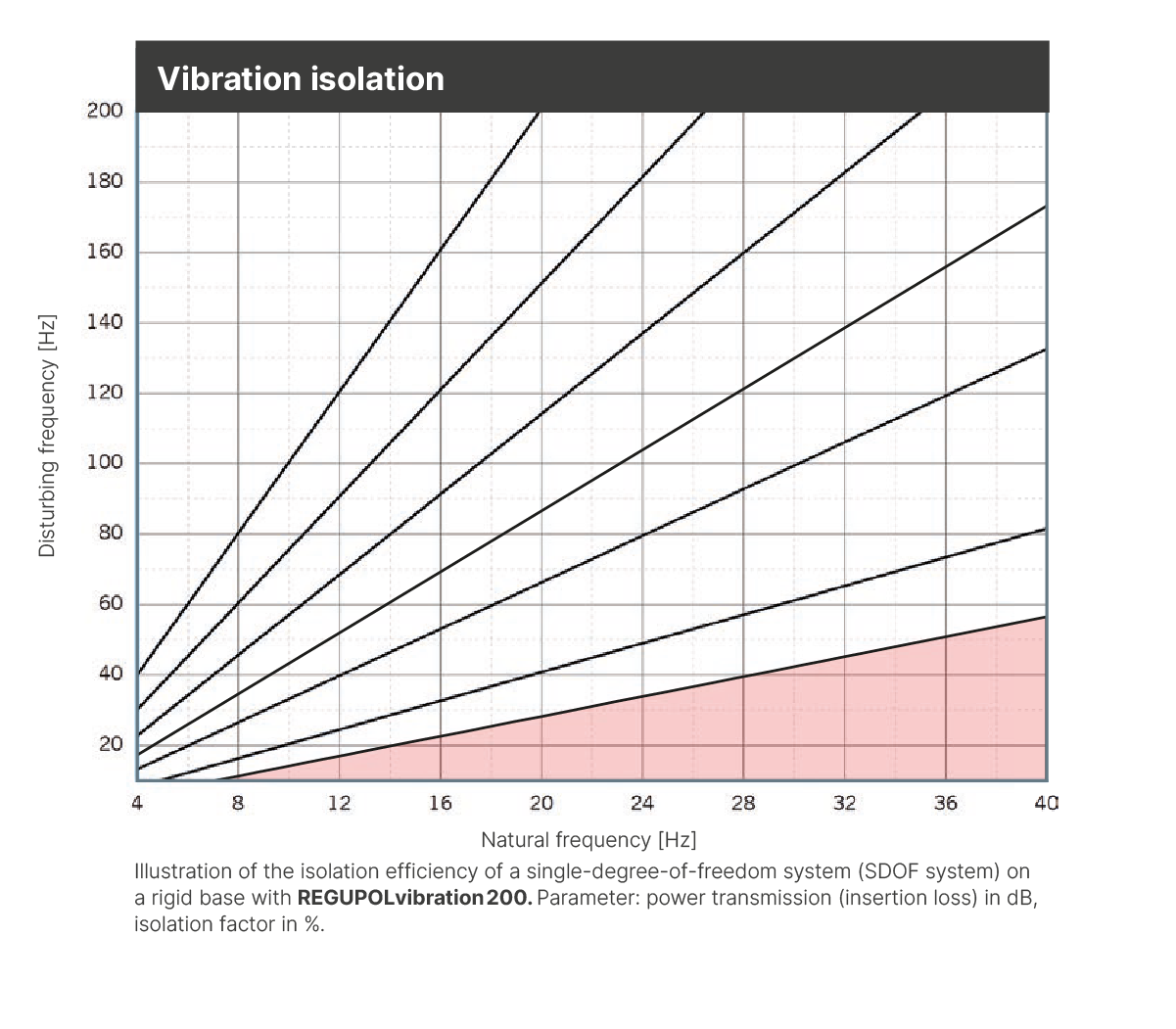

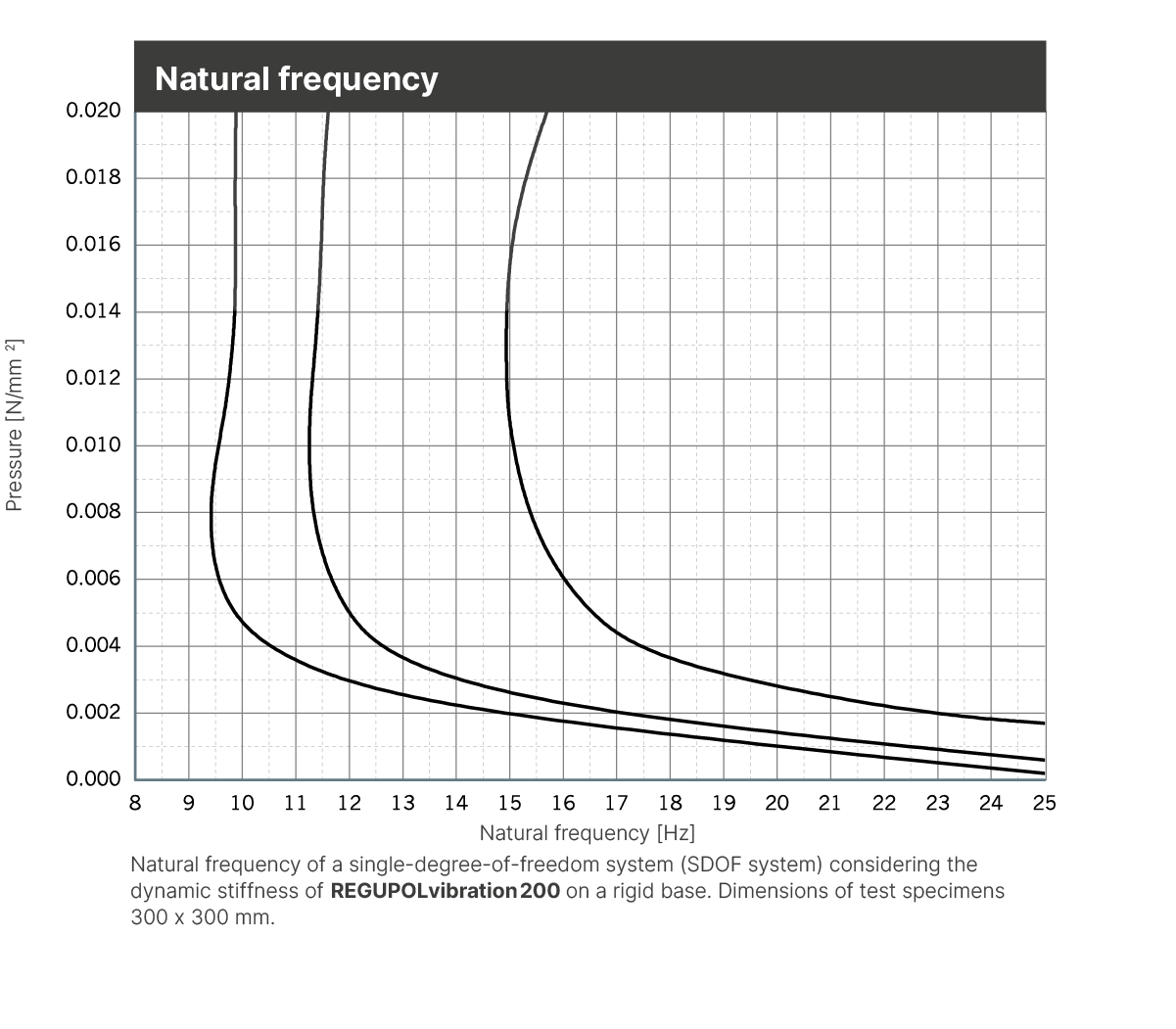

The approved material REGUPOL vibration 200 is used in the load range up to 0.02 N/mm². Depending on load and material thickness, natural frequencies of 10 Hz can be achieved.

REGUPOL vibration 200 is a vibration isolation and structure-borne sound decoupling material for the load range up to 0.02 N/mm². It can be used in single or multiple layers to achieve natural frequencies of down to 10 Hz, depending on load and material thickness.

Product Characteristics

Continuous static load

0.02 N/mm²

Peak loads (rare, short-term loads)

0.05 N/mm²

Protect the material against moisture.

Standard forms of delivery, ex warehouse

Rolls

Thickness: 17 mm, dimpled

Length: 10,000 mm, special lengths available

Width: 1,250 mm

Sheets/Strips/Pads

On request: Die-cutting, water-jet cutting, self-adhesive versions possible

Technical Specifications

Regupol-Vibration-200-specifications regupol-vibration-200-specifications.xlsx

Regupol Vibration 300

| Physical property | Norm | Result | Comment |

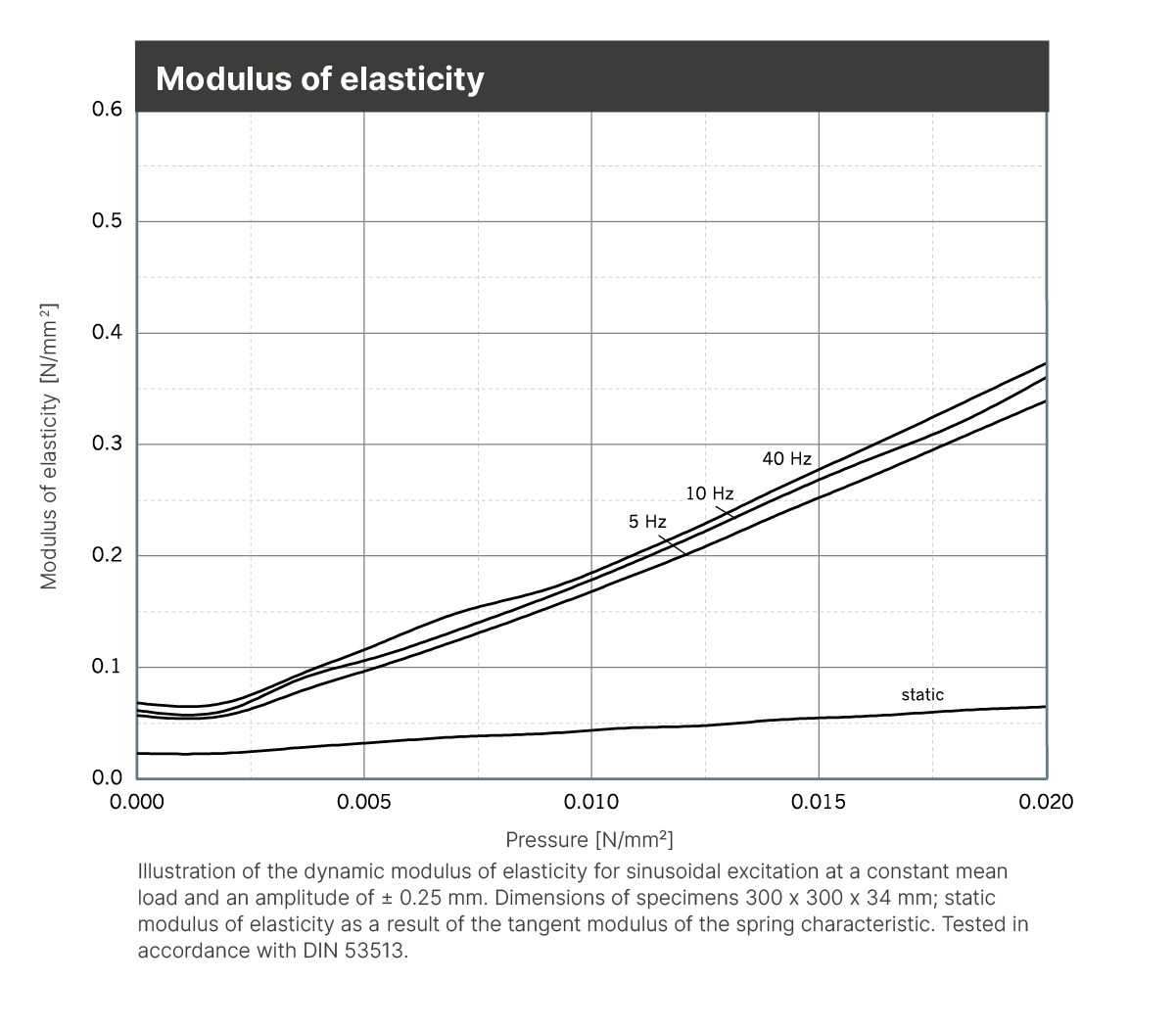

| Static modulus of elasticity | Based on EN 826 | 0.02 - 0.08 N/mm2 | Tangential modulus, see figure “modulus of elasticity” |

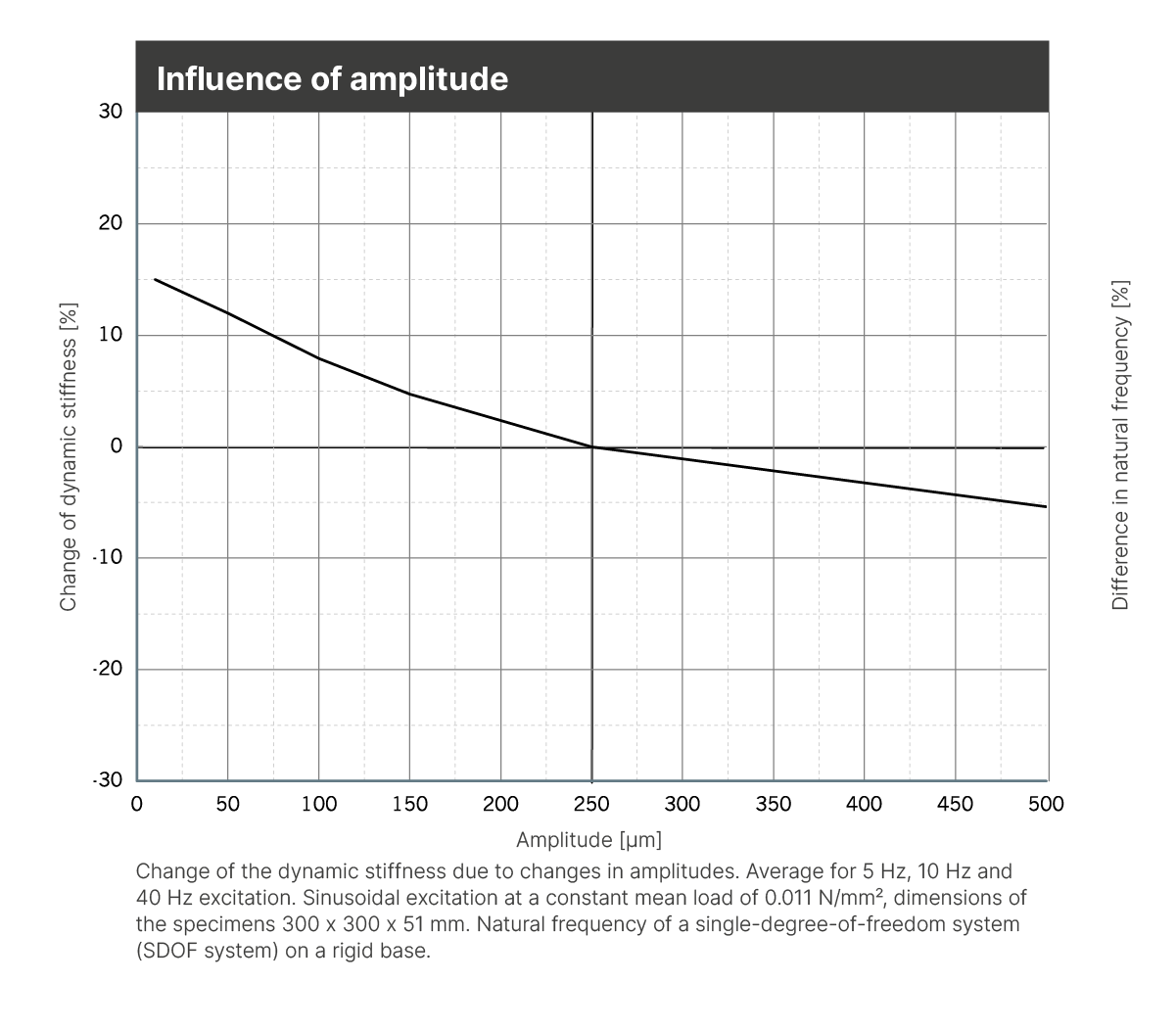

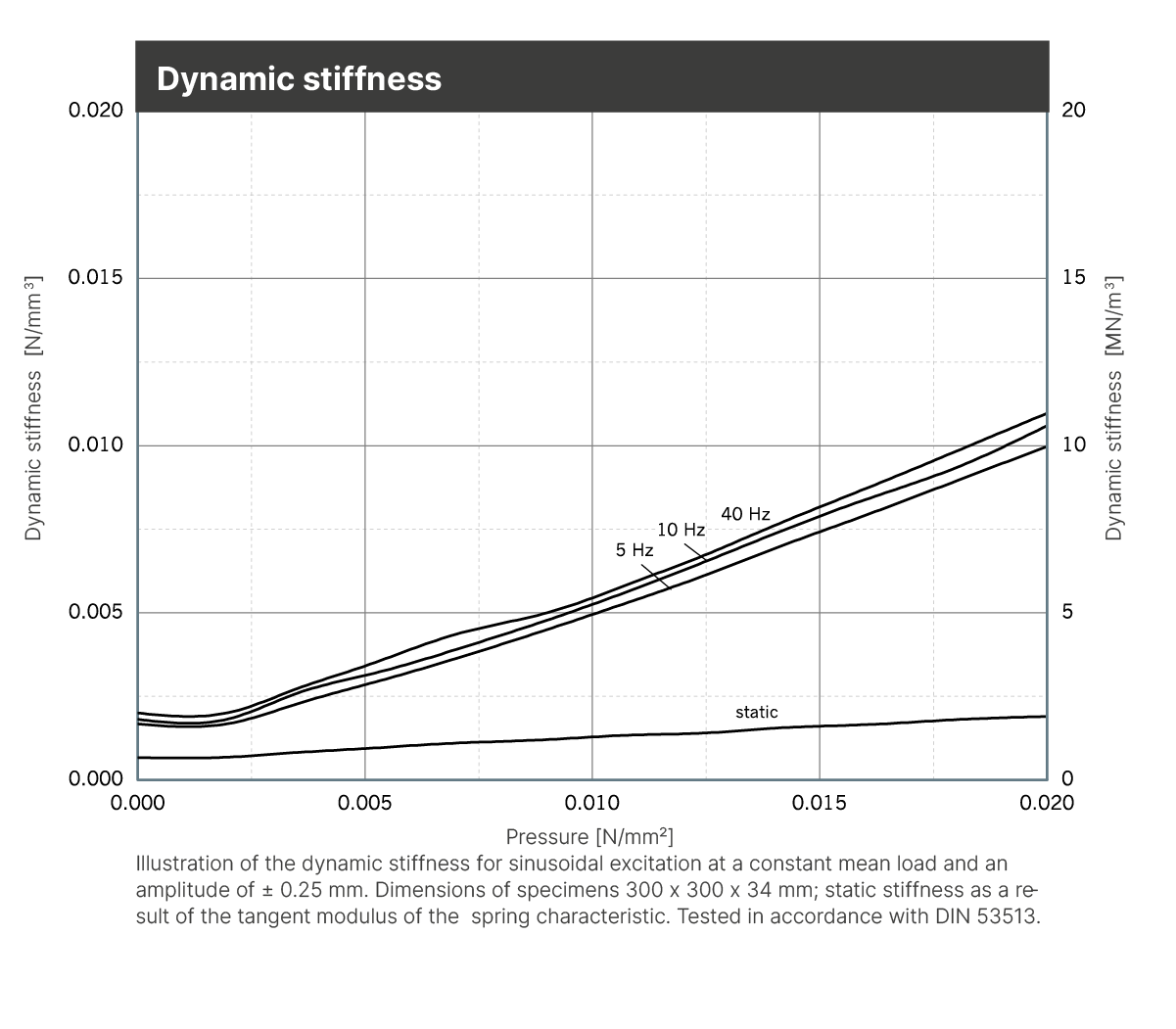

| Dynamic modulus of elasticity | Based on DIN 53513 | 0.05 - 0.38 N/mm2 | Depending on frequency, load and thickness, see figure “dynamic stiffness“ |

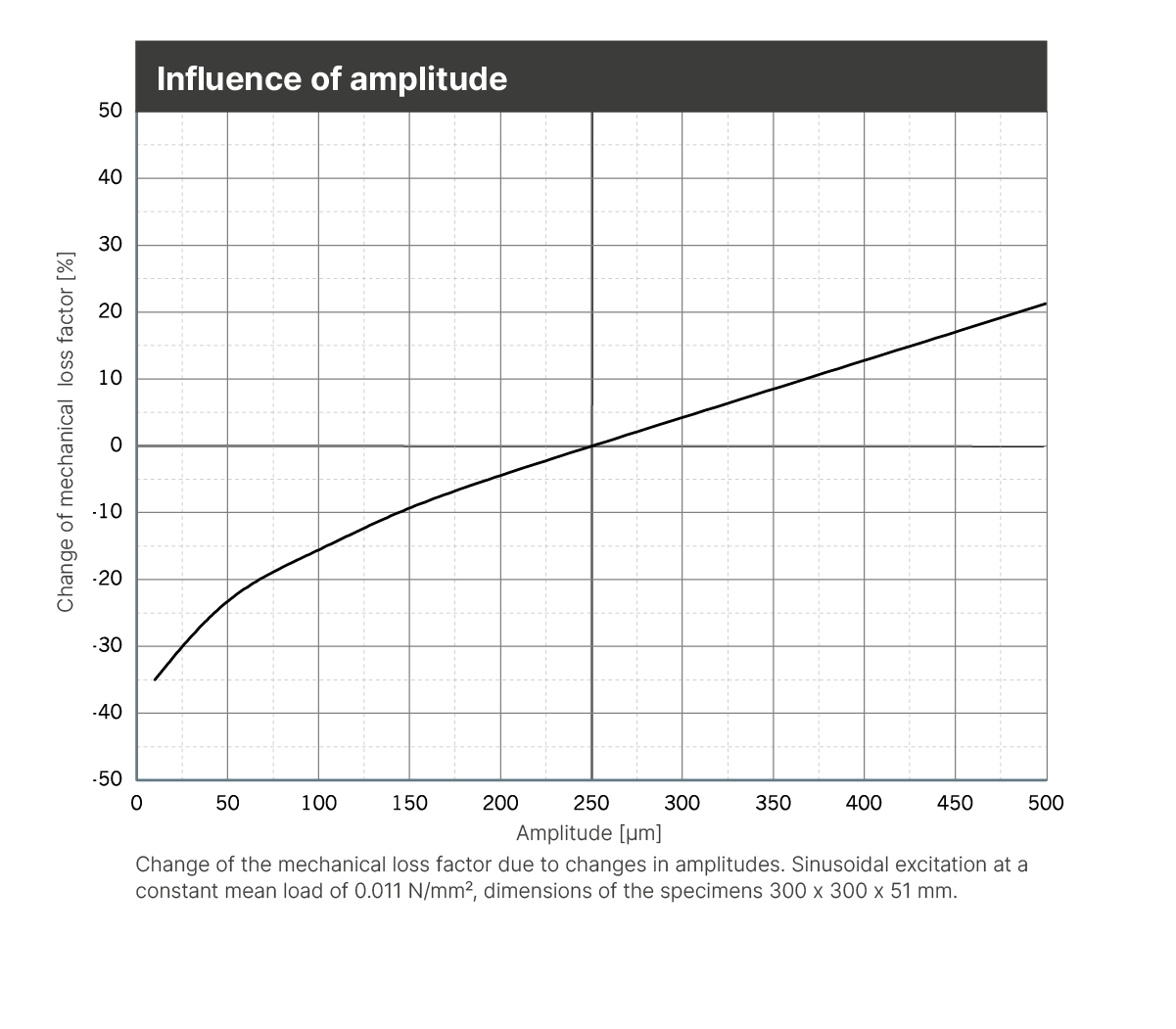

| Mechanical loss factor | DIN 53513 | 0.22 | Load-, amplitude- and frequency-dependent |

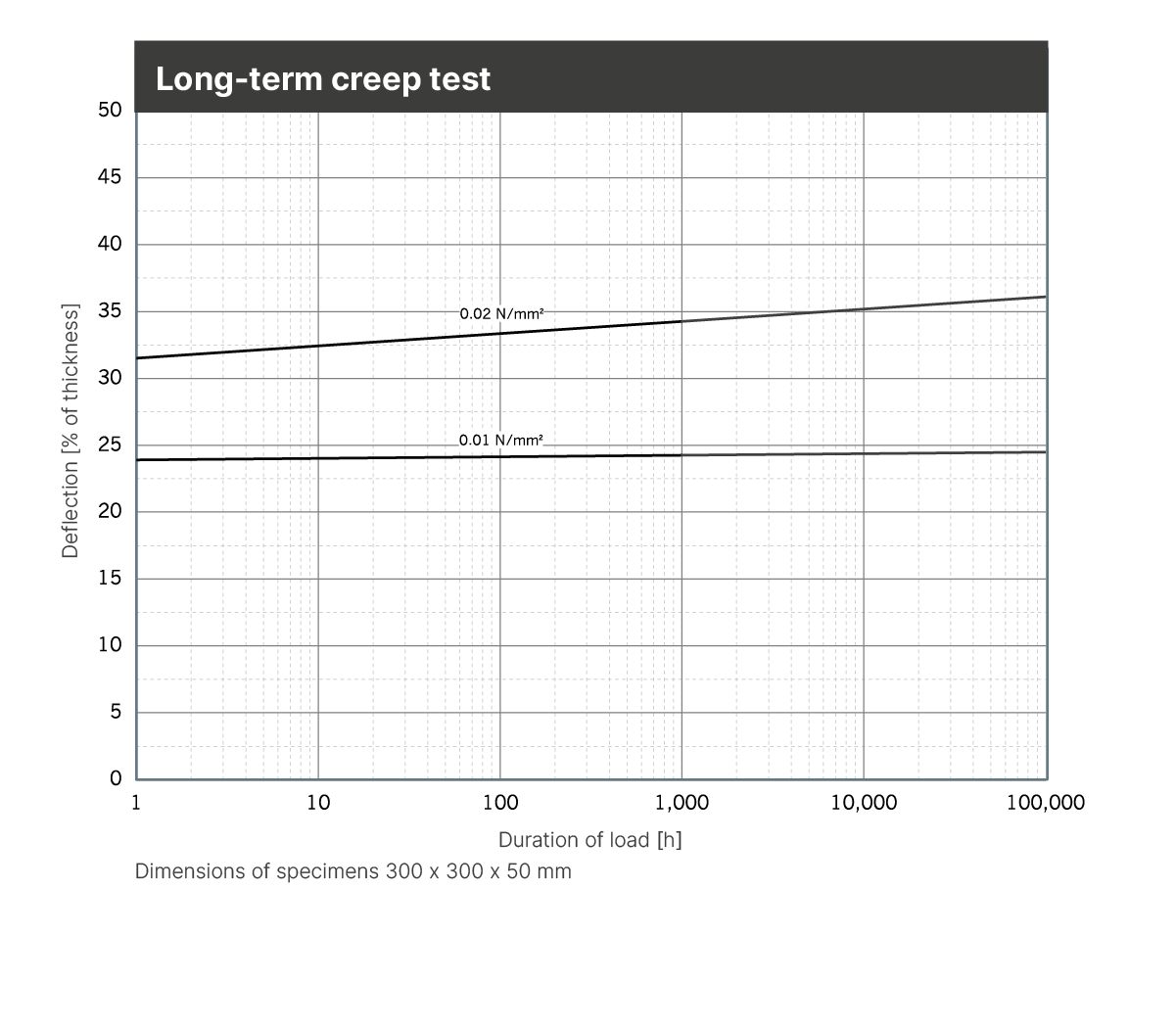

| Compression set | Based on DIN EN ISO 1856 | 3.1 % | Measured 30 minutes after decompression with 50 % deformation / 23 °C after 72 hrs |

| Tensile strength | Based on DIN EN ISO 1798 | 0.12 N/mm2 | |

| Elongation at break | Based on DIN EN ISO 1798 | 40% | |

| Tear resistance | Based on DIN ISO 34-1 | 1.0 N/mm | |

| Fire behaviour | DIN 4102 | B2 | |

| DIN EN 13501-1 | E | ||

| Sliding friction | REGUPOL-laboratory | 0.7 | Steel (dry) |

| REGUPOL-laboratory | 0.8 | Concrete (dry) | |

| Compression hardness | Based on DIN EN ISO 3386-2 | 14 kPa | Compressive stress at 25 % deformation test specimen h = 51 mm |

| Rebound elasticity | Based on DIN EN ISO 8307 | 14% | dependent on thickness, test specimen h = 51 mm |

| Force reduction | DIN EN 14904 | 73% | dependent on thickness, test specimen h = 51 mm |

| Ozone resistance | DIN EN ISO 17025 | Cracking stage 0 |