Regufoam Vibration Isolation

Regufoam® vibration is an elastic polyurethane foam designed for optimal vibration isolation. It is available in twelve different densities and various thicknesses, now including thinner options, offering even more flexibility to suit diverse needs.

Regufoam 810

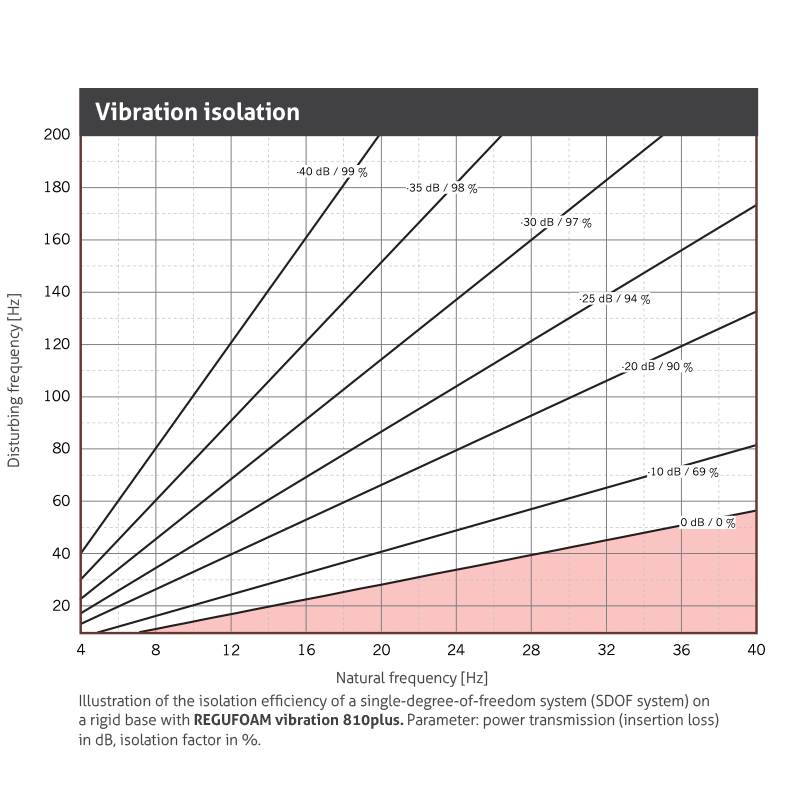

Areas of application include building base isolation, isolation of machines and equipment, structure borne noise created by activities like people moving, dishwashers, washing machines and electronic devices, particularly in multi-storey wooden buildings. By integrating vibration insulation with Regufoam, these disturbances can be reduced.

Product Characteristics

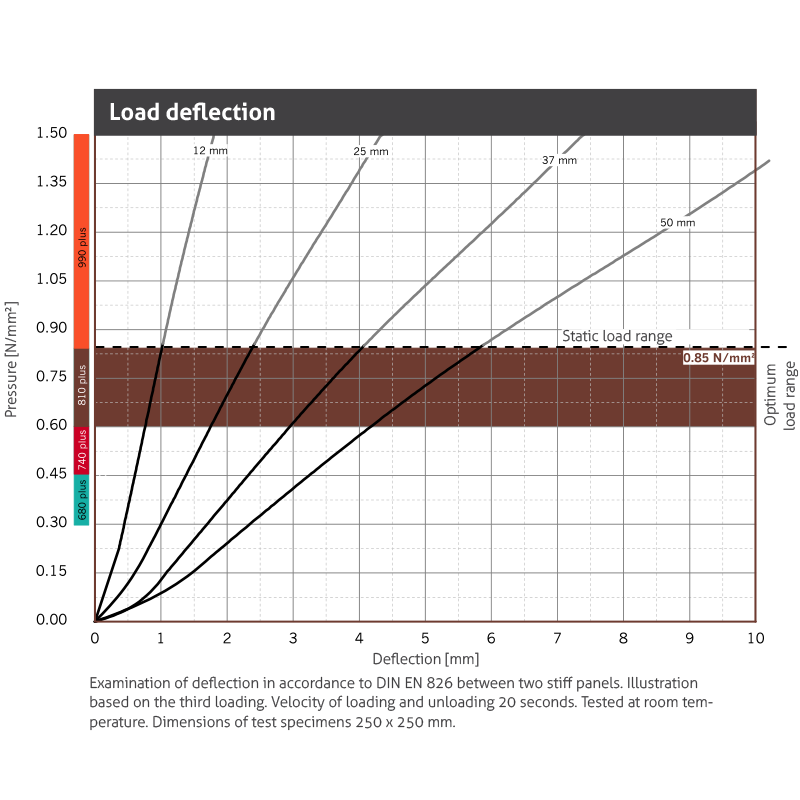

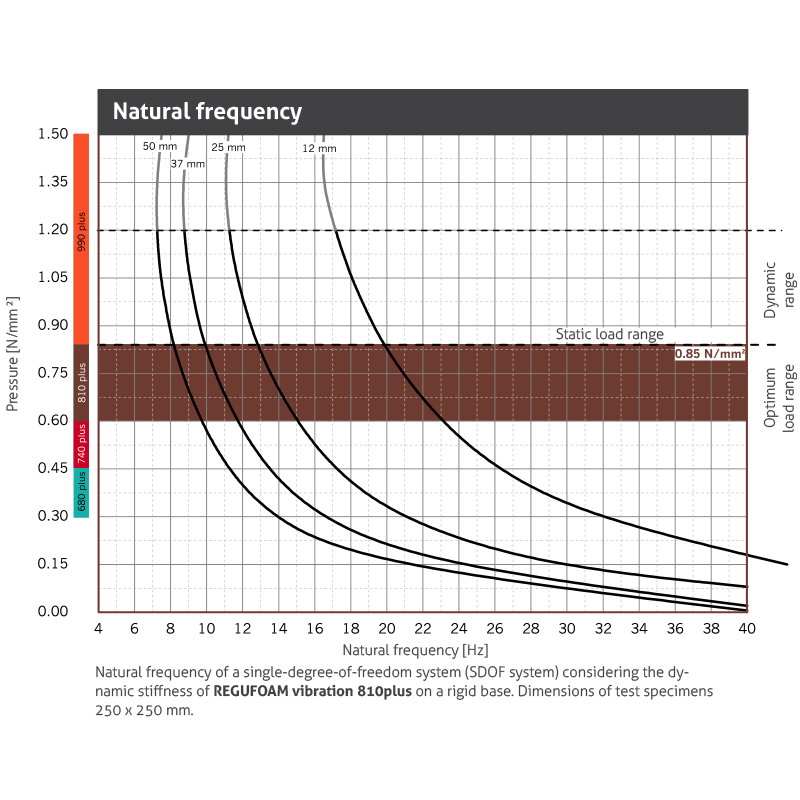

Continuous static load

0.85 N/mm²

Continuous and variable loads/operating load range

0 to 1.20 N/mm²

Peak loads (rare, short-term loads)

up to 7 N/mm²

Standard forms of delivery, ex warehouse

Sheets

Thickness: 12.5 and 25 mm are standard, and regularly available off the shelf. Special thicknesses on request

Length: 1500 mm, special lengths available on request

Width: 1000 mm

Strips or pads

On request: Die-cutting, water-jet cutting, self-adhesive versions possible

On request we can tailer to your needs and produce 75, 50, 37.5, 25, 12.5, 6 mm all the way down to 2 mm thicknesses.

Technical Specifications

regufoam-810-specifications.xlsx

Regufoam 810

| Physical property | Norm | Result | Comment |

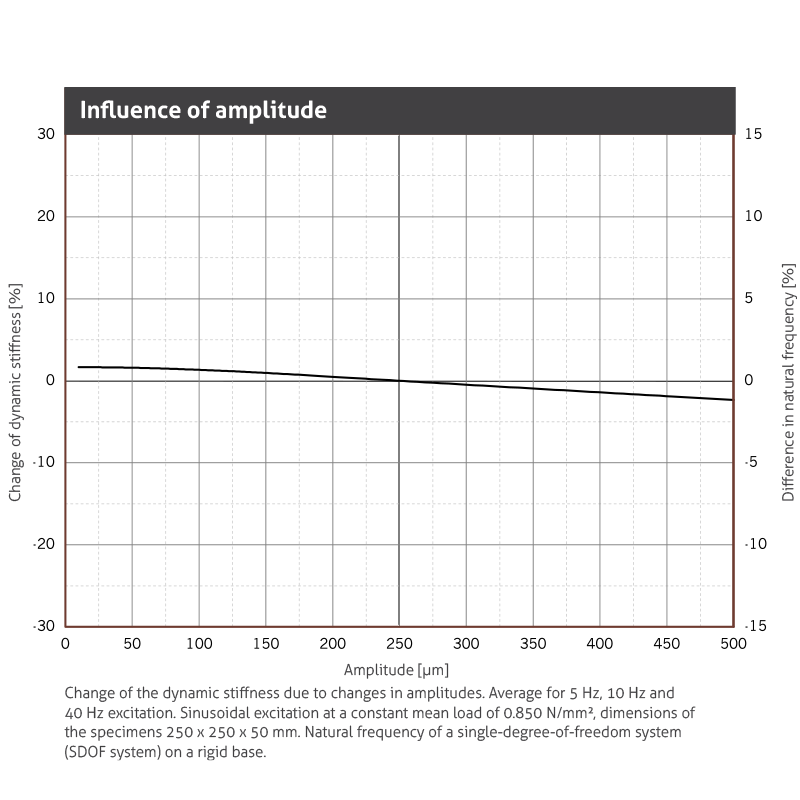

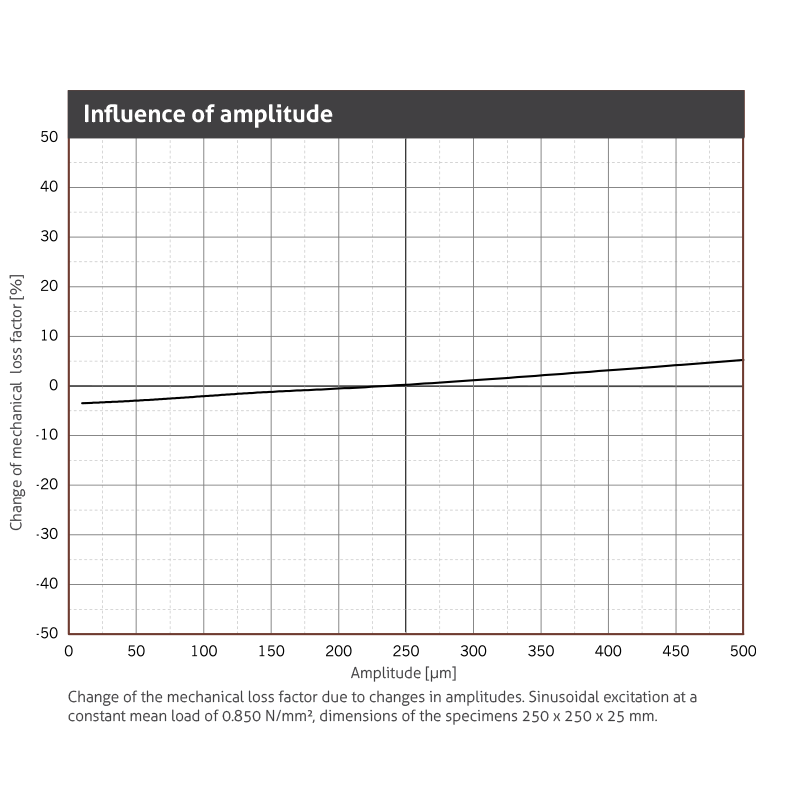

| Static modulus of elasticity | Based on EN 826 | 5.4 - 8.0 N/mm2 | Tangential modulus, see figure “modulus of elasticity” |

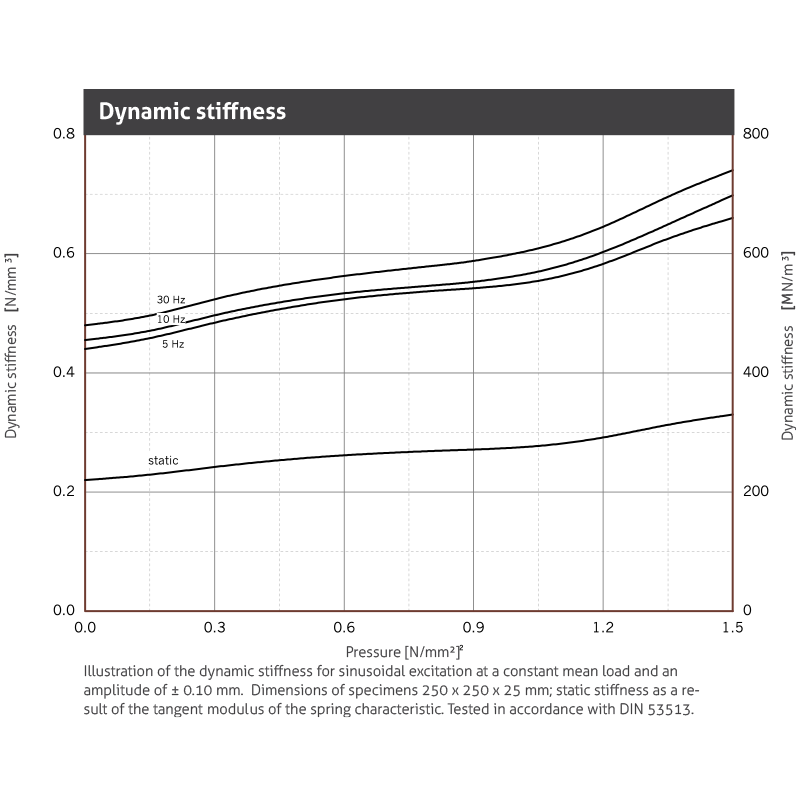

| Dynamic modulus of elasticity | Based on DIN 53513 | 11.0 - 16.5 N/mm2 | Depending on frequency, load and thickness, see fi gure “dynamic stiffness“ |

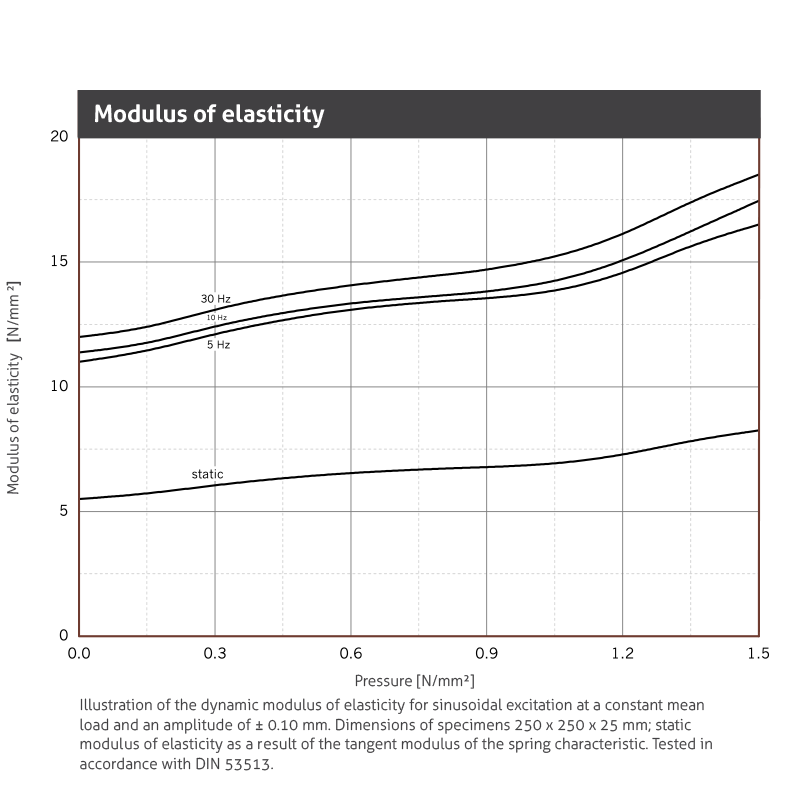

| Mechanical loss factor | DIN 53513 | 0.10 | Load-, amplitude- and frequency-dependent |

| Compression set | Based on DIN EN ISO 1856 | 7.9 % | Measured 30 minutes after decompression with 50 % deformation / 23 °C after 72 hrs |

| Tensile strength | Based on DIN EN ISO 1798 | 4.6 N/mm2 | |

| Elongation at break | Based on DIN EN ISO 1798 | 230% | |

| Tear resistance | Based on DIN ISO 34-1 | 20.0 N/mm | |

| Fire behaviour | DIN 4102 | B2 | |

| DIN EN 13501-1 | E | ||

| Sliding friction | REGUPOL-laboratory | 0.6 | Steel (dry) |

| REGUPOL-laboratory | 0.75 | Concrete (dry) | |

| Compression hardness | Based on DIN EN ISO 3386-2 | 1241 kPa | Compressive stress at 25 % deformation test specimen h = 25 mm |

| Rebound elasticity | Based on DIN EN ISO 8307 | 58% | dependent on thickness, test specimen h = 25 mm |

| Force reduction | DIN EN 14904 | 35% | dependent on thickness, test specimen h = 25 mm |