Damping Glue DG-2000

Product Characteristics

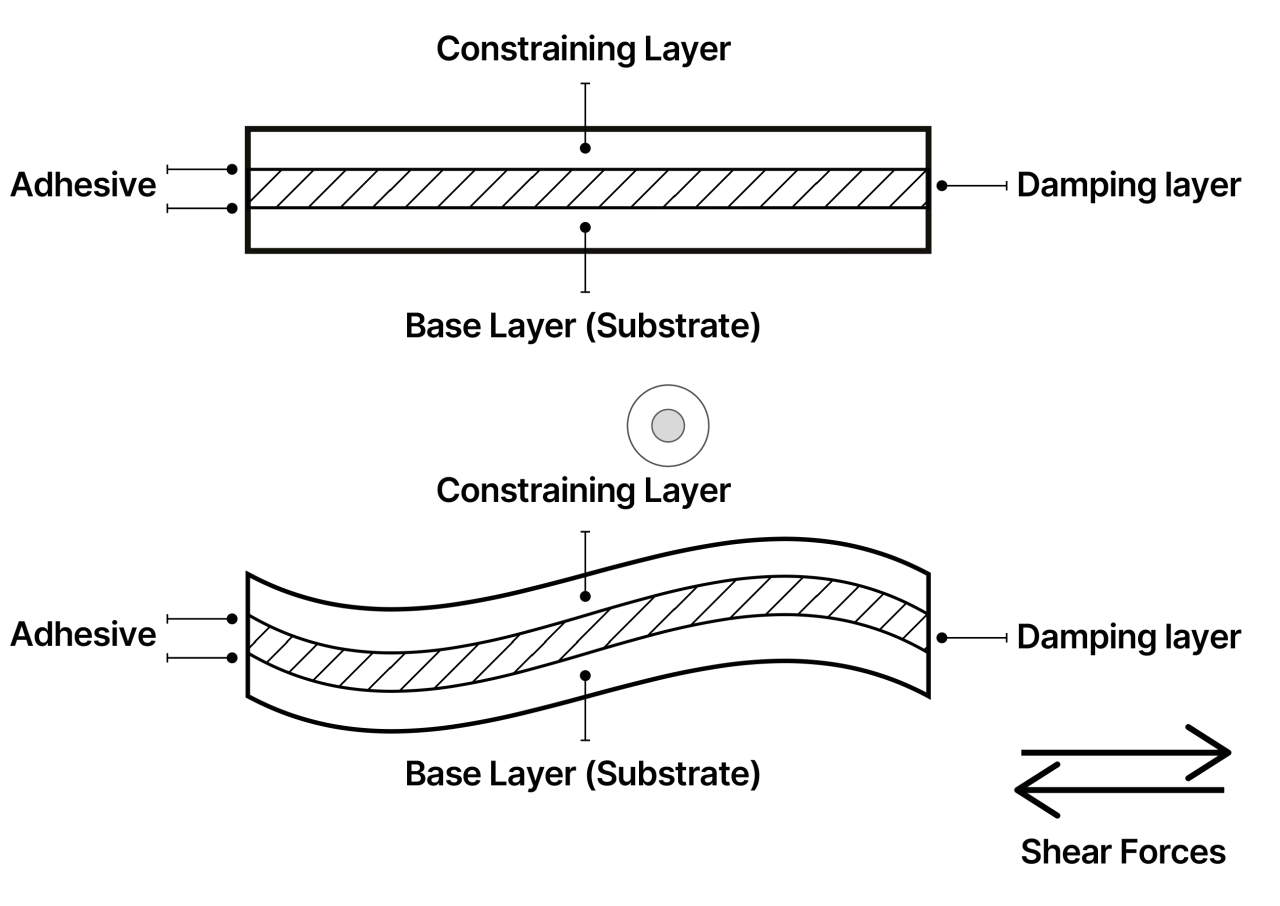

DG-2000 is a water-based acrylic damping glue optimised for wooden based constrained layer damping applications. Stiff sheet materials used for floor and wall constructions, like plywood, chipboard and plasterboard have very low damping. These materials / constructions therefore easily generate resonant structure borne vibrations, which causes noise radiation and fatigue problems.

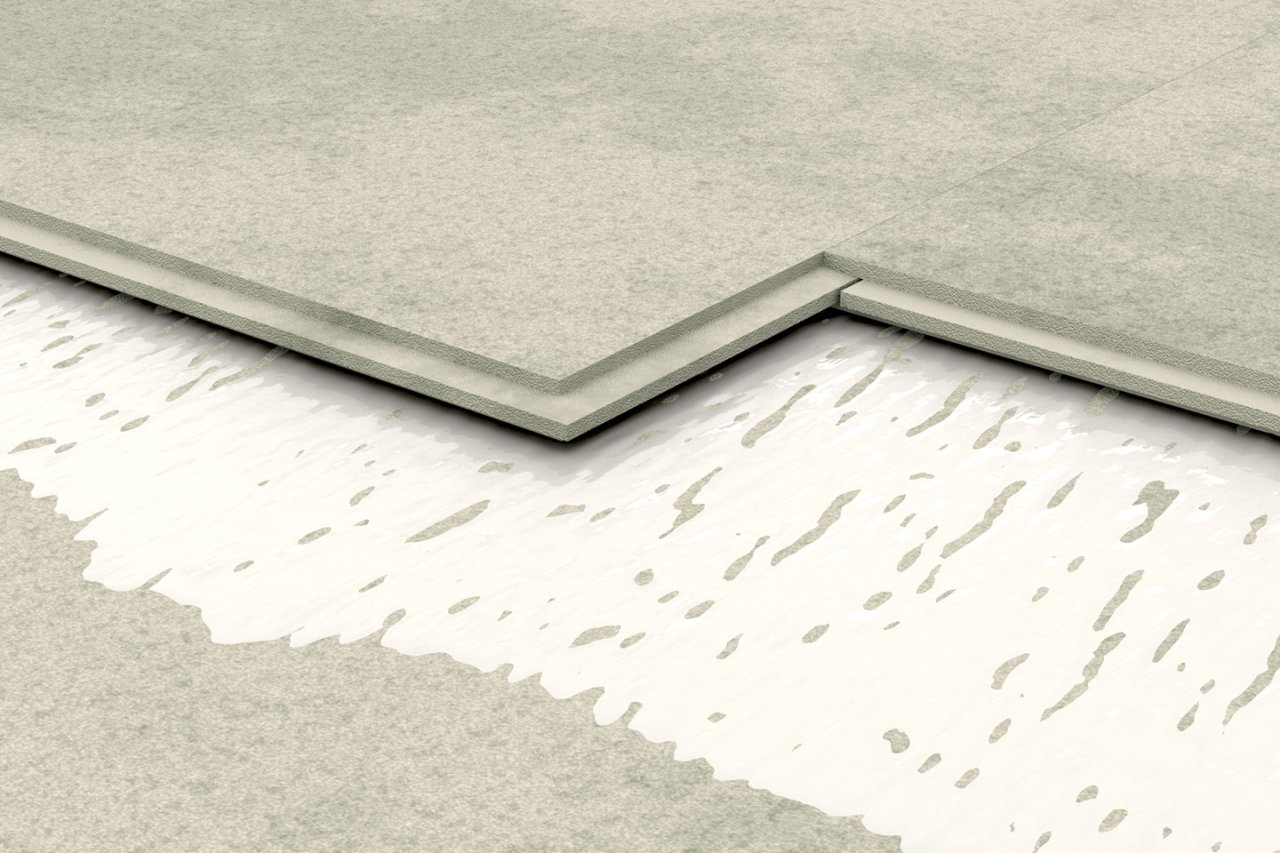

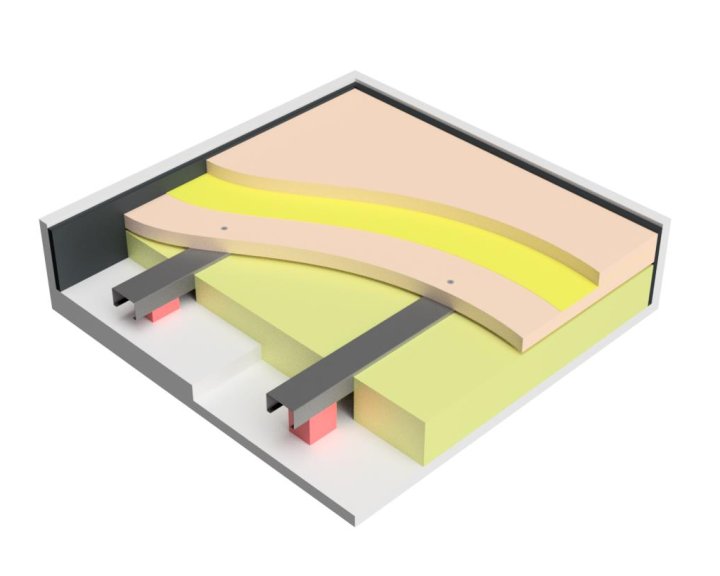

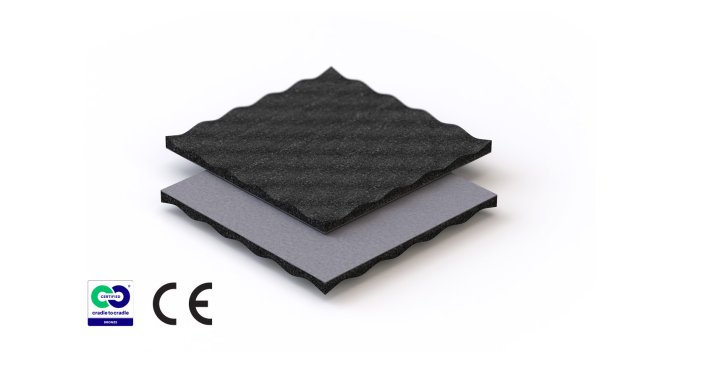

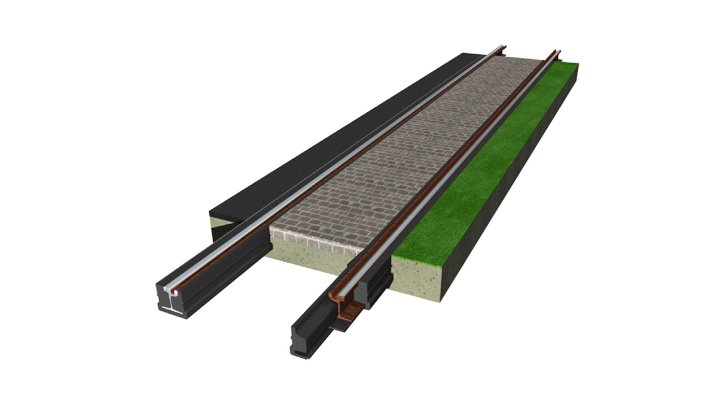

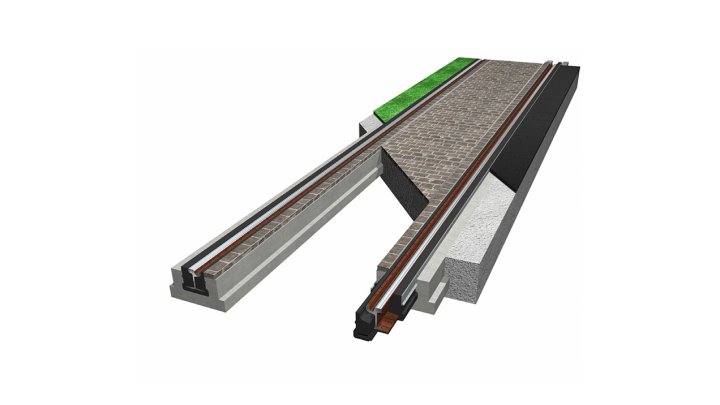

DG-2000 should be used in a sandwich construction, where DG-2000 is constrained between two sheets of for example plywood. DG-2000 is easy to apply and the loss factor of your construction will be increased and the radiated noise will be decreased.

Product Applications

- Structural damping of floors in bus and rail vehicles, stages and walls.

- Impact damping of floors, e.g. in buildings and trains.

- Increased transmission loss of walls and doors.

- Further more is the glue an excellent solution for loudspeaker constructions.

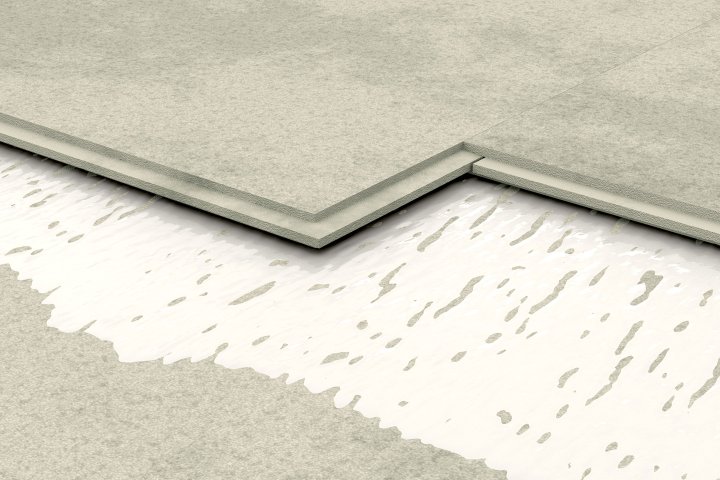

The thickness ratio between the constraining layers should be 1:3. However it is actually the stiffness ratio that is of interest. About 1 kg/m2DG-2000 should be applied, preferable by a roller or toothed trowel, between two sheet of for example plywood, chipboard, or MDF. This gives a damping layer of about 1 mm thickness.

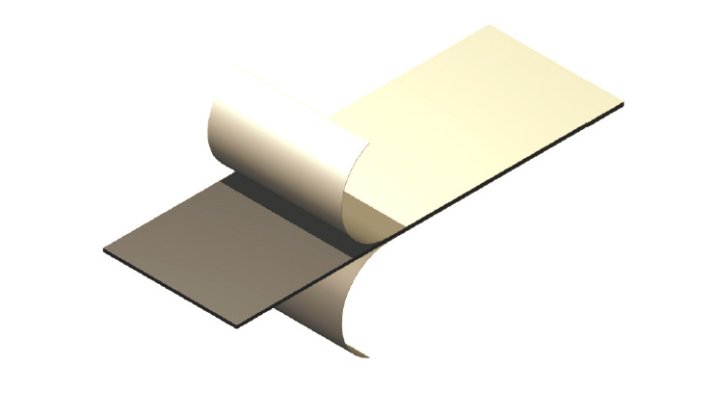

The surfaces of the two sheet materials should be joined together while the glue is still wet and held under firm contact (maximum pressure about 30 KN/m2).

When gluing sheets on site, the top sheet may be nailed or screwed tightly to the structure layer. Ensure that there is no air cavities trapped between the two sheets. It is important to note that the bending stiffness of the damped structure is lower than a homogenous sheet with equal thickness.

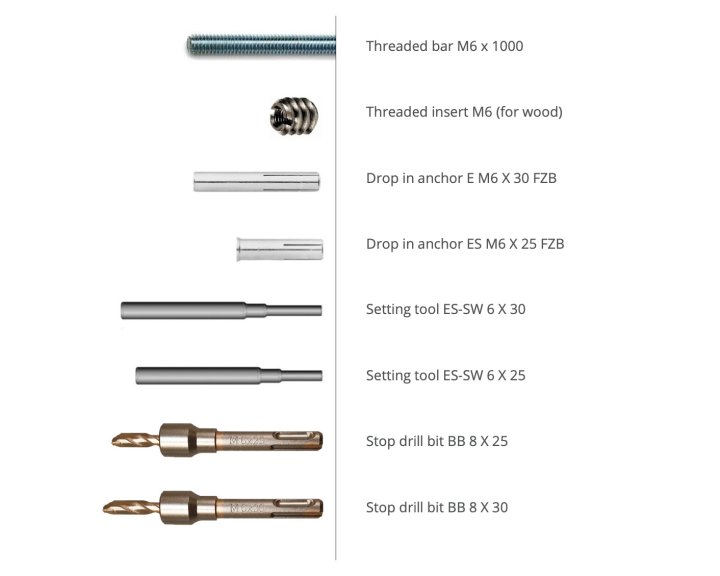

It is possible to drill holes or cut the laminated sheet in the same way as a homogenous sheet.

Pre-treatment of surface: Clean the surface free from dirt and dust.

Acoustic Properties

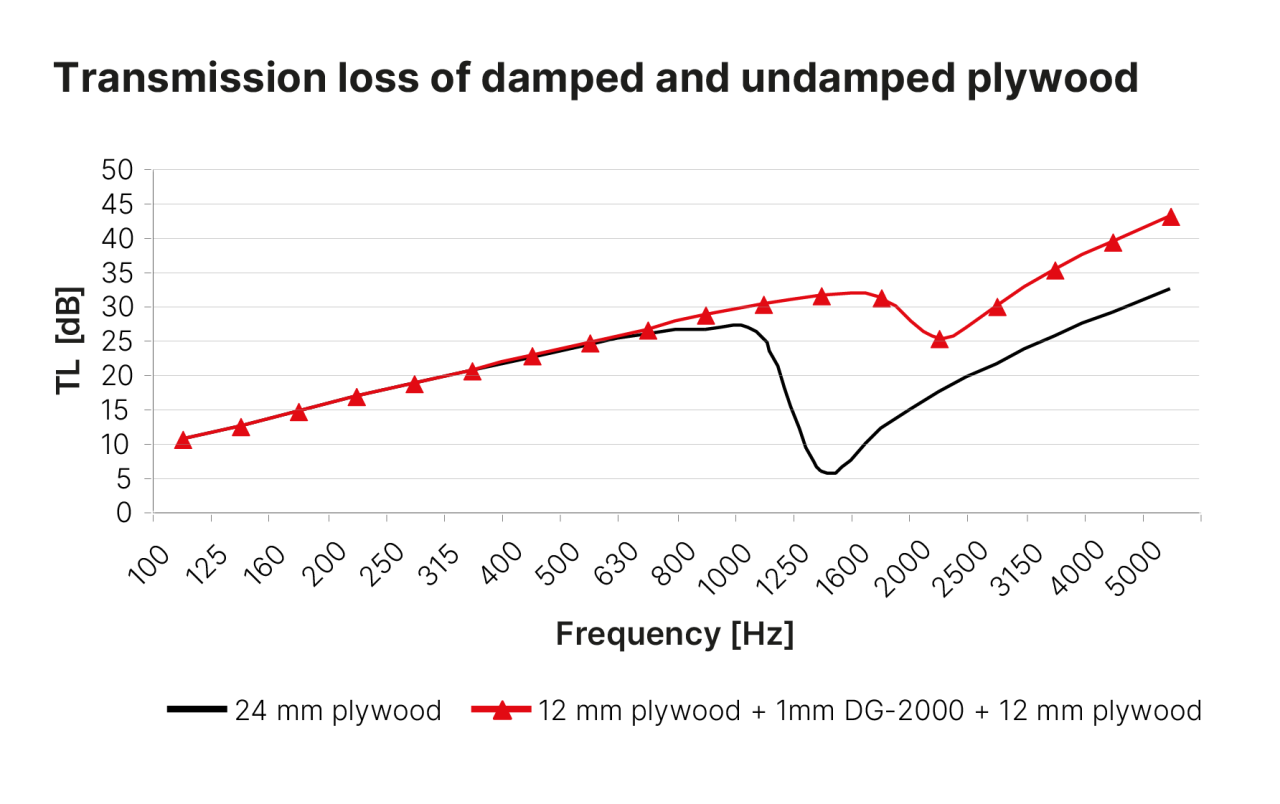

For a single sheet construction the airborne noise transmission loss is mainly determined by the surface weight of the sheet. Below the coincidence frequency, the transmission loss will theoretically increase by 6 dB per octave and with 6 dB per doubling of the area weight. Above the coincidence frequency the damping loss factor of the sheet is mainly driving the transmission loss. This can clearly be seen in the graph below.

The performance of DG-2000 is like all viscoelastic damping materials heavily dependent on frequency and temperature. DG-2000 has a high loss factor over a wide temperature and frequency range and is therefore a good choice for many applications.

Technical Specifications

DG-2000 technical specificationsdamping-glue-dg-2000-technical-specifications.xlsx

Properties

| Colour | Whitish |

| Solvent | Water |

| Density (dry) | ~ 1300 kg/m3 |

| Density (wet) | ~ 1050kg/m3 |

| Flammability: | Non-flammable |

| Solid content | ~ 80 % by weight |

| Drying time at 20°C | 5 to 7 hours (about 35 minutes at 80°C, in a heated press.) |

| Storage | Can be stored at least one year in unopened containers |

| (Protect from frost!) | |

| Size | 16kg |

Downloads

Contact Us

Interested in Damping Glue DG-2000?

Feel free to contact us for more information