Constrained Layer Damping

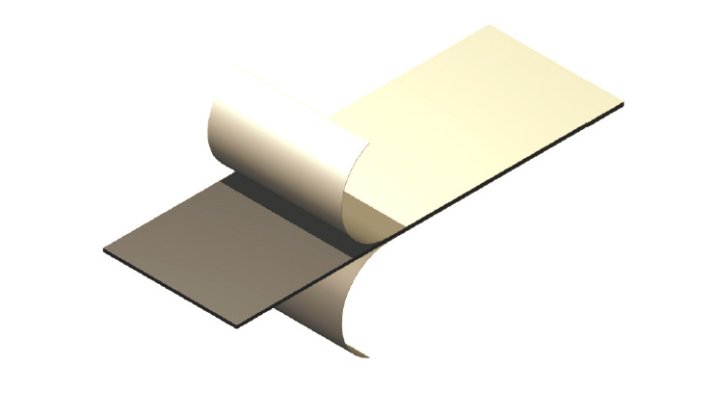

Constrained-layer damping (CLD) systems are used to increase damping in stiff structures. A “sandwich” is formed by laminating a damping layer in between two structural constraining base layers. When the system flexes during vibration, shear strains develop in the damping layer and energy is lost through shear deformation of the material. Varying layer thickness ratios permits optimizing system loss factors for various temperatures without changing the material’s composition.

Vibratec can offer several sorts of damping layers cut and punched according to client specification. Also visco elastic glue can be used for sandwich layering.

-

Constrained Layer Damping Tiles

Constrained-layer damping (CLD) tiles are used to increase damping in stiff structures. A “sandwich” is formed by laminating a damping…

-

Sandwich Layer CLD14 – CLD21

CLD 14 concists of a bitumen mat with self adhesive and paper release on both sides. Comes in 2 thicknesses;…

Related News

News archiveInterested in Constrained Layer Damping

Feel free to contact us for more information